The game of cricket revolves around both bat and ball. Bowlers try to dismiss the batsmen with the ball, while batters strike the ball with his bat by defending, attacking or simply leaving it. Do you know various types of cricket balls used in Cricket and how cricket balls are made?

A ball roughly weighs in between 155.9 and 163 grams, while its circumference ranges between 22.4 and 22.9 centimeters.

In earlier days, the red-ball was used in both Test cricket and ODI cricket. With the era of colored clothing coming into practice, white balls are now used during limited-overs fixtures.

There are often comparisons made between the red ball and the white ball, in terms of swing and seam. To promote Day-Night game, now Pink balls have also come into the reckoning. The attributes of a pink ball are still under research.

Today, let’s have a look at the different types of balls used in international cricket and how Cricket Balls are made.

Types of Balls:

1. The Dukes’ Ball

Dukes’ ball is the oldest out of all balls used in cricket. The origin of the ball dates back to 1760 when the production started in the United Kingdom. The color of the ball is darker when compared to the others. The ball is entirely handmade and is the most durable as the ball takes a longer period of time to get old. The likes of James Anderson and Stuart Broad have profited the most as it assists seamers in overcast English conditions.

The seam holds good upto 50 to 56 overs and provides swing to the seamers. It also bounces more as compared to other balls. Dukes ball achieves the greatest magnitude of movement in conditions of England.

Which countries use it?

England and West Indies

2. The Kookaburra Ball

Kookaburra was established in 1890 and has been a chief manufacturer of cricketing goods in the last 128 years. The Kookaburra ball is internationally acclaimed as the number one ball manufacturer. The first time the Australian Cricket Board used kookaburra balls was during the 1946/47 Ashes series. Its factory is based in Melbourne, which uses some of the finest raw materials using state of the art facilities.

Unlike the Dukes’, the Kookaburra is entirely made using machines. The seam of the Kookaburra is the least prominent when compared to other different types. However, the ball assists pace bowlers with movement up to 30 overs.

Which countries use it?

Australia, South Africa, Pakistan, Sri Lanka and South Africa.

Also Read: What is Umpires Call and how it works?

3. The SG Ball

SG is the abbreviation for Sanspareils Greenlands ball. The SG used to manufacture sports items initially. After independence, the company moved to (Meerut), India. In the year 1991, the BCCI approved the SG balls for test cricket. Since then, the Tests in India are played with this ball.

SG balls have a wider seam which is closer together because ticker thread is used to make them. Even now the balls are handmade and have upright seam which remains in good condition even after one day of play. These balls lose the shining because of dry conditions in India. These balls are helpful for spinners because of wider seam. After the shine goes off, it helps the bowler with a lot of reverse swing up to 40 overs.

Which countries use it?

Only India.

4. Pink Ball

Pink Ball is the most talked ball and is the most recent addition. Red ball won’t work if matches are to be played in night. Under the floodlights, they appear another color that can be confusing and also have poor visibility which can trouble the batsman. Pink balls were introduced to counter that problem.

It preserves the color for a longer time and also remains longer than red balls. These factors combined make the pink ball an ideal ball to play with in day-night test cricket. Like the red ball, it is also pace-friendly with good seam, swing, and bounce. Currently all Test playing nations started playing some matches with this ball.

How Cricket Balls are made?

There are two questions which I’m sure you have always wanted to know the answers to: What’s inside a cricket ball, and how are they made? Well, wonder no more.

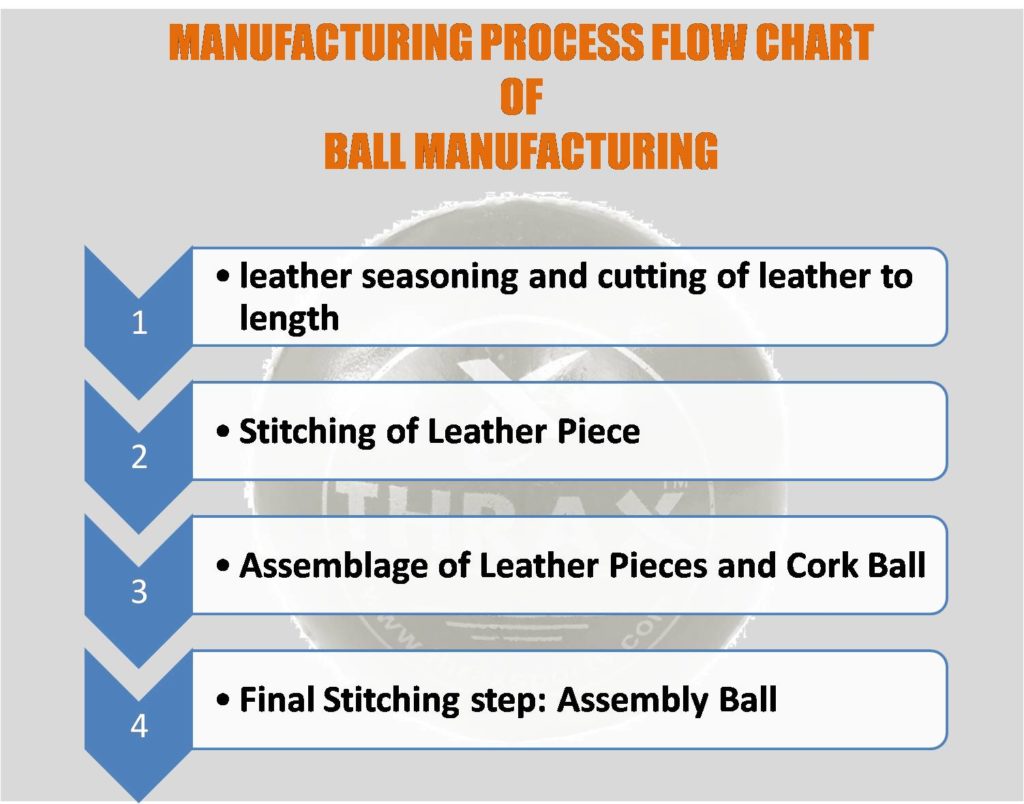

Similar to a planet, a cricket ball is made up of different layers. Procedure of making Cricket balls is listed below:

Firstly, a chunk of cork comprises the hard core of the ball, and this is turned into a spherical shape by being covered with tightly wound string. Next, after all of the components have been weighed to ensure they are within the universal guidelines for a cricket ball (155.9-163.0 grams for a men’s ball), the four pieces of leather are pieced together and the “equator” is stitched with string to form a raised seam.

The leather is then dyed, stamped with the maker’s name and covered with multiple coats of polish, ready to be delivered into the hands of eager seam bowlers around the world.

While machines have no doubt made certain aspects of the job easier over the years, most cricket ball manufacturers still handcraft large elements of their merchandise. Now the whole thing is clear. Various types of Cricket Balls used in cricket and how these cricket balls are made.